The Helium leak test, where we manufacture vacuum components, is part of our manufacturing process. We use Helium leak testing to find small leaks or larger leaks in larger volumes. Helium is used as a tracer gas and its concentration is measured, helping us to produce better quality sealing equipment.

Leakage is defined as uncontroll entry or exit of fluid from a small hole in the system or from several connection parts of the system. The leak rate depends on several factors such as the size of hole/holes, gas type, the pressure difference (Between the inside and the outside of the system.) The detection and elimination of leaks is extremely important for a number of reasons, including:

• Operator safety (egression of toxic gases/fluids)

• Product safety (sometimes if air enter a system, it may significantly contribute the formation

of n explosive mixture. So this should be prevented.)

• To ensure a long user-life product

• To satisfy and maintain pressure/vacuum

• For process efficiency

• For environmental and quality standards

• Reducing Costs

A test using helium as tracer gas is called ‘Helium Leak Test’. This method is currently the most sensitive leak detection method commercially avaliable in the market. It has several avantages suc as being non-destructive, highly reproducible and faster than many other methods. Helium test can be used the determination of the leak at from the leakage rate of 1*10-6 mbar*lt/s to the leakage rate of 1*10-12 mbar*lt/s.

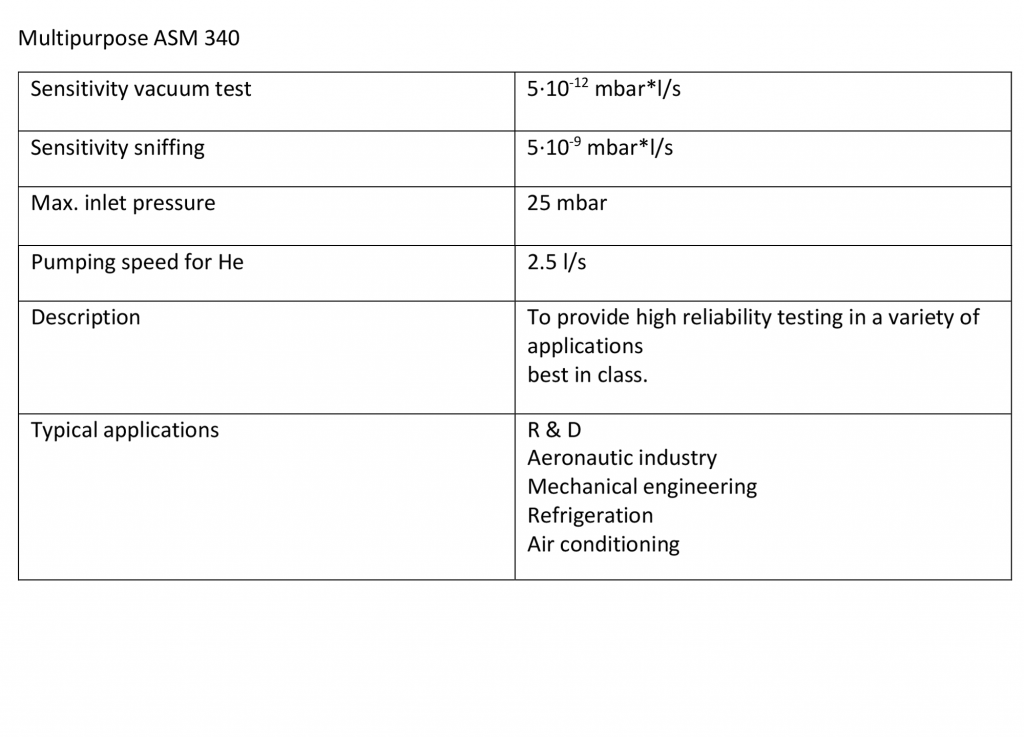

There are many reasons why helium gas is used as a tracer gas. Due to the small structure of helium gas moleculus, they have the capacity to pas seven through the smallest space. Therefore, the use of helium gas as tracer gas gives us high sensitivity. At the same time, Helium is an environmentally friendly gas since it does not react with the surrounding substances as an inert gas. In addition, this gas is not toxic gas and is not flammable, making helium a good choice. Leak detection with helium gas is done in two ways. While the first of these is the “Vacuum Method”, the other is the “Sniffer Method” In the vacuum method process, the inside of the part to be tested is vacuumed and helium gas is sprayed with a sprayer to the points where there may be leakage from the outside (i.e. welded areas, flanges, portals, connection points, etc.). Helium gas entering the vacuumed test piece from the leakage zones is sent to the mass spectrometer for recording. In the method we call the sniffer method, the inside of the tested part is pressurized to a certain level with helium gas. After this process, the possible leakage points are scanned with the help of a sniffer and it is determined whether there is any leakage. Helium gas detected by the sniffer is sent to the mass spectrometer for recording. For the Helium Leak Test service provided by our company, Multipurpose ASM 340 which belongs Pfeiffer Vacuum Company is used.

In addition, during the test, we use Apiezon brand grease that we represent. We can close the leak we have detected with this special oil (Apiezon Q compound) and investigate whether there is a different leak until the test is concluded. This both increases quality and reduces costs.

Apiezon Q compound

Putty material

Easy to use

Excellent waterproof medium

Used wherever a vacuum leak needs to be temporarily plugged